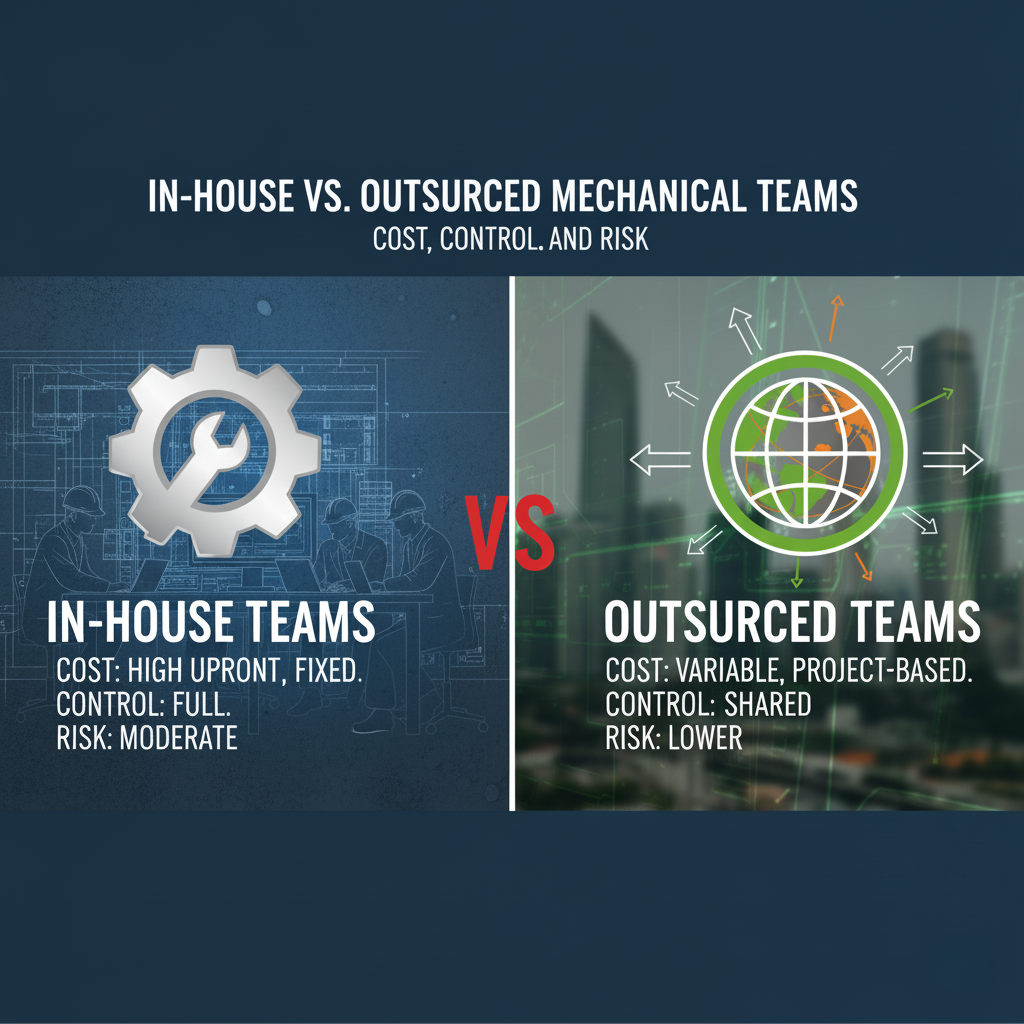

In-House vs. Outsourced Mechanical Teams: Cost, Control, and Risk

A Strategic Guide to Cost, Control, and Risk

A Strategic Guide to Cost, Control, and Risk

Choosing between an in-house mechanical team and an outsourced mechanical team is a pivotal decision that affects budgets, timelines, and product quality. Hiring full-time engineers under your roof gives you direct control and preserves institutional knowledge, while partnering with external design experts offers flexibility and specialized skills. Understanding the trade-offs in cost, control, and risk helps you find the right balance for your product development process.

In this guide, we’ll define each model, compare direct and indirect costs, explore collaboration and risk factors, share real-world case studies, and provide a decision framework with a practical matrix. By the end, you’ll have clear insights and cost modeling tips to choose the model that drives better first-pass yield and supports continuous improvement.

An in-house mechanical team consists of salaried engineers who work exclusively for your company. You control their day-to-day activities, training, and career development. In contrast, an outsourced mechanical team involves contracting with external design partners or engineering firms. These partners may charge hourly rates, retainers, or fixed project fees.

Hybrid approaches combine both—using in-house staff for core competencies and outsourcing overflow or niche expertise. Key terms to remember include headcount (the number of full-time employees), bill-rates (hourly fees for consultants), project-based engagements (fixed-fee scopes), and service-level agreements (SLAs) that define deliverables and quality metrics.

If you are evaluating external partners for your product development roadmap, it’s helpful to use a structured framework. The Mechanical Design Partner Scorecard: 12 Criteria OEMs Should Vet offers a comprehensive checklist and scoring method to guide partner selection decisions.

With an in-house mechanical team, direct costs include salaries, benefits, taxes, and office overhead. Fully burdened hourly rates often range from $80 to $150 per hour when benefits and overhead are factored in. By contrast, outsourced mechanical teams typically charge $100–$200 per hour depending on their specialty and geographic location. Retainers or fixed-fee contracts can smooth out these rates but may include premium fees for guaranteed capacity.

In-house staff require recruiting expenses, onboarding time, and ongoing training. Management must spend time mentoring and reviewing work. Outsourcing introduces its own indirect costs—vendor onboarding, travel expenses for meetings, and potential communication inefficiencies. However, these can be minimized with clear SLAs and robust collaboration strategies.

To compare accurately, calculate fully burdened rates for both models. Build a simple spreadsheet template that includes salary, benefits, overhead, and recruiting amortized over expected billable hours. For outsourced teams, include onboarding fees and travel costs. Use variable versus fixed cost scenarios—outsourcing offers flexibility when project volume spikes, while an in-house team spreads costs evenly.

An in-house mechanical team offers daily oversight—you can walk over to a designer’s desk and review CAD models together. Outsourced mechanical teams require structured reporting: weekly status updates, milestone reviews, and remote collaboration tools. Clear SLAs help ensure transparency.

In-house staff build institutional expertise and protect internal IP. When you offload work to external partners, there’s risk of knowledge loss as projects transition between vendors. Mitigate this by enforcing drawing standards, GD&T protocols, and using PLM/PDM systems to capture design data centrally.

Embedding company culture, design guidelines, and quality checks is more straightforward with full-time engineers. For outsourced teams, share your template checklists, CAD libraries, and product manufacturing information (PMI) to align on expectations. Kickoff workshops and weekly checkpoints keep both teams on the same page.

Use agile sprints and daily stand-ups for in-house teams, while outsourced partners benefit from formal kickoff meetings and weekly progress calls. Digital platforms like cloud-based PLM systems support real-time feedback, file sharing, and issue tracking.

In-house teams follow your process controls and maintain consistent quality. Ensuring vendor adherence to drawing standards and manufacturing workflow is critical to prevent rework. Conduct regular design reviews and require sample deliverables before full engagement.

Internal capacity constraints can create bottlenecks when multiple projects coincide. Outsourced vendors may offer faster turnaround but introduce risk of delays due to their other commitments. Include contractual penalties or SLAs to manage delivery timelines.

Employees operate under your confidentiality policies and have secure access. With external partners, enforce NDAs, secure data exchange protocols, and limited access to sensitive repositories. Use encrypted file transfers and restrict CAD model permissions.

Scaling headcount up or down with in-house staff is slow and costly due to hiring cycles. Outsourced mechanical teams shine in flexibility—they can ramp up resources quickly to meet peaks and troughs in workload without long-term commitments.

A consumer electronics company used its in-house mechanical team to build early prototypes rapidly, leveraging deep product knowledge. For assembly-level refinements and tooling design, they engaged an outsourced mechanical team with injection-molding expertise. The hybrid approach balanced cost, preserved core IP, and accelerated time-to-market.

An industrial pump manufacturer outsourced detailed FEA and CFD studies to a specialized engineering firm, while its in-house team handled integration drawings and CNC programming. This division of labor provided access to niche expertise, managed risk, and improved first-pass yield from 70% to 90%.

When a product defect threatened a scheduled launch, the fully staffed in-house team was overloaded. An external partner delivered a critical redesign in two weeks, preventing a costly delay. Though outsourcing cost more per hour, the avoided lost revenue justified the premium.

Ask these four guiding questions to select your team model:

| Criteria | In-House Preferred | Outsourced Preferred | Hybrid Approach |

|---|---|---|---|

| Cost Predictability | High | Low | Medium |

| Scalability | Low | High | High |

| Control & IP Security | High | Medium | High |

| Access to Expertise | Medium | High | High |

| Time-to-Market Speed | Medium | High | High |

Balancing cost modeling, control, and risk is key to choosing between in-house, outsourced, or hybrid mechanical teams. Align your decision with your business goals, project complexity, and IP sensitivity. Start with a small pilot, define clear metrics, refine your collaboration strategy, and adjust as your needs evolve. A well-matched team model accelerates innovation, optimizes budgets, and reduces the risk of shop-floor rework and delays—driving your product development process toward greater efficiency and success.